Scenery:

Ground Goop

I am often asked what exactly am I using when I refer to Ground Goop. I will make no creator's claim in the discovery of this technique and simply say that this recipe has been around for some time. Lou Sassi has published this material several times over the years in the pages of various hobby magazines.

1 Cup Celluclay

1 Cup Vermiculite (Home Depot or Lowes, lawn & garden)

1 Cup Flat latex paint (the desired soil color)

1/2 Cup Elmer’s regular white glue - NOT school glue

1 Capful Liquid Lysol

I have substituted Sculptimold for the Celluclay in the past and it works fine, but in my opinion it is easier to work with the Celluclay mix. The Sculptimold mix was very lumpy and it proved difficult to get a smooth finish in some areas.

The original recipe called for Perma Scene. This is no longer available, but the fine Vermiculite found at Home Depot or Lowes is a good substitute. The Vermiculite provides additional volume to the mix.

The capful of Lysol is very important. This material will keep forever as long as it is in a sealed container. All you will need to do is add a little water and work it back into the material. If you don't add the Lysol though, you may likely have a layer of scenery already growing when you open the container!

I always work with latex gloves and keep a small bowl of water handy when I am working with ground goop. If you need to soften it slightly, simply dipping your hand in the water and then back onto the goop will be enough to spread the material. NOTE - You don't want the ground goop to be too soupy otherwise as it dries it will crack and pull away from some areas.

Track Painting

My technique for painting track has, in my opinion, improved significantly from my first approach on the Trowbridge module to what I am currently working on today. I have opted to place this section in to serve as a running documentation of my method and approach.

STEP 1 - PRIMER COAT:

I determine what type of track this will be and the look I want to achieve. From here this determines the color of primer coat that I will apply. As a rule of thumb, I use the following colors...

Mainline with newer ties - Rustoleum Camo Brown

Mainline with older ties - Rustoleum Khaki

Sidings and Secondary - Rustoleum Primer Gray or similar

|

| Mainlines and Spur Track on Bancroft Module |

|

| Newer Mainline ties on the Tappan Module |

STEP 2 - RAIL PAINTING:

Next, I paint the rail with an airbrush getting as close as possible to avoid completely painting the ties. A little overspray is welcome as it will serve to represent the rust colors that bleed into the ties under and around the tie plates. For rails, I use the following colors...

Mainline - Tamiya XF-68 Nato Brown

Sidings and Secondary - Tamiya XF-10 Flat Brown

After the primer has had a chance to completely dry (generally 24 hrs.) I begin with my first tie wash application. For this I use Water Mixable Oils thinned with Odorless Mineral Spirits. The three main colors I use...

Burnt Umber

Lamp Black

Burnt Sienna

I start with a small shallow bowl of Odorless Mineral Spirits and then I squeeze a small amount of each color around the rim. I can then mix and match colors as desired. Eventually the mineral spirits become a soupy mixture of all the colors which is perfect for this application. I just try and keep the mixture thinned with the spirits so that it washes over the ties and settles into all of the surface detail of the ties. For this application I generally saturate everything including the rails. If this initial wash dries and appears to light for my taste, then I simply add an additional was until I am satisfied.

I allow the initial wash application to dry completely before I begin with the next step which is tie color variation. For this step I usually only use the Burnt Umber and Lamp Black Water Mixable Oils.

I run my brush into the color I want and then only dip it into the mineral spirits to wet it. I then apply it to individual ties randomly. Most will get the Burnt Umber in varying degrees of color with the occasional Black tie to represent the brand-new ties most recently replaced.

Roads

There

are many different ways to model roads, and I don't really stick with one

specific technique when modeling them although I do tend to favor the use of

styrene. Probably more important than anything when building roads is that they

are modeled true to scale. An excellent source of reference material to help

get correct road dimensions can be found at any state's Department of

Transportation (DOT) websites.

COLOR: I use rattle can Rustoleum Primer and paints for most of my roads. The Rustoleum colors I generally stick with are the Dark Gray, and Light Gray. Additionally I use White and any Beige color that is close to a concrete color.

(A note of caution on white spray paints: The white pigments tend to clog spray paint nozzles very easily. They usually work fine the first time you use them, but once they have sat for an extended period of time they will spray poorly. With this in mind, spend extra time cleaning the nozzle when finished with these paints. If possible, have a second nozzle that can be rotated onto the can. Clean the used nozzle by immersing it in a small jar of mineral spirits. ALWAYS TEST YOUR SPRAY CANS AGAINST A PIECE OF CARDBOARD BEFORE ATTEMPTING TO PAINT MODELS!)

I will determine how old the road will be and select the primer closest to that color for the base coat.

The first step is to paint the concrete curbs and sidewalks if all attached.

Next I will mask off the road surface and paint it whatever color that I have selected for the base coat.

Once the base coat is dried, I will go back over the entire assembly with "mists" of lighter or darker colors as appropriate to achieve the final desired color. The trick here is to spray in quick passes from about two to three feet above the surface rather than the normal 10-16 inches directed on spray cans. The idea behind this is that the paint begins to dry before it lands on the surface of the road. The result is a granular look. Continue to build up subsequent layers using light coats of various colors until the desired look is achieved. Once you are satisfied, lock it in with a coat of Testor's Dull Cote, or Model Masters Lusterless Flat. Let it dry overnight.

Mask off the traffic lines to represent the appropriate / desired schematic. I paint these with a rattle can as well. NOTE: Yellow paint will show up better if you first spray the lines white. After the white has completely dried, go back over with yellow.

I used colored pencils and fine tipped markers next to draw the cracks in the asphalt. For deeper cracks or potholes you will want to have these in place prior to the base coat.

The final step is additional weathering using weathering powders until satisfied with the final look. Once everything is to your liking, again lock it in with Dull Cote or Lusterless.

The example below is a four-lane road that I built for Mr. Joe Balint's module for the Sipping and Switching Society of NC. The scene, and the bridge are loosely based on the bridges common along the GTW Right of Way. Unfortunately, these pictures were taken prior to completion so there are still details (such as grade crossing gates and bridge chevrons) that had not yet been added. This entire road was built from styrene. The road itself is a sheet of .060 styrene. The curbs are HO Scale 6"x6"strips rounded on the top edge with a file. Lines were taped off and painted using rattle cans. The patch work is various pieces of styrene glued to the surface.

The next example is a road on the opposite side of the same module which was done by Mark Gugliotta, another one of the prominent members of the Sipping & Switching Society. For this road surface Mark used Elmer's Wood Putty. Once the putty has dried, the road is shaped using a sanding block. Mark then painted the road using the same method as stated above.

COLOR: I use rattle can Rustoleum Primer and paints for most of my roads. The Rustoleum colors I generally stick with are the Dark Gray, and Light Gray. Additionally I use White and any Beige color that is close to a concrete color.

(A note of caution on white spray paints: The white pigments tend to clog spray paint nozzles very easily. They usually work fine the first time you use them, but once they have sat for an extended period of time they will spray poorly. With this in mind, spend extra time cleaning the nozzle when finished with these paints. If possible, have a second nozzle that can be rotated onto the can. Clean the used nozzle by immersing it in a small jar of mineral spirits. ALWAYS TEST YOUR SPRAY CANS AGAINST A PIECE OF CARDBOARD BEFORE ATTEMPTING TO PAINT MODELS!)

I will determine how old the road will be and select the primer closest to that color for the base coat.

The first step is to paint the concrete curbs and sidewalks if all attached.

Next I will mask off the road surface and paint it whatever color that I have selected for the base coat.

Once the base coat is dried, I will go back over the entire assembly with "mists" of lighter or darker colors as appropriate to achieve the final desired color. The trick here is to spray in quick passes from about two to three feet above the surface rather than the normal 10-16 inches directed on spray cans. The idea behind this is that the paint begins to dry before it lands on the surface of the road. The result is a granular look. Continue to build up subsequent layers using light coats of various colors until the desired look is achieved. Once you are satisfied, lock it in with a coat of Testor's Dull Cote, or Model Masters Lusterless Flat. Let it dry overnight.

Mask off the traffic lines to represent the appropriate / desired schematic. I paint these with a rattle can as well. NOTE: Yellow paint will show up better if you first spray the lines white. After the white has completely dried, go back over with yellow.

I used colored pencils and fine tipped markers next to draw the cracks in the asphalt. For deeper cracks or potholes you will want to have these in place prior to the base coat.

The final step is additional weathering using weathering powders until satisfied with the final look. Once everything is to your liking, again lock it in with Dull Cote or Lusterless.

The example below is a four-lane road that I built for Mr. Joe Balint's module for the Sipping and Switching Society of NC. The scene, and the bridge are loosely based on the bridges common along the GTW Right of Way. Unfortunately, these pictures were taken prior to completion so there are still details (such as grade crossing gates and bridge chevrons) that had not yet been added. This entire road was built from styrene. The road itself is a sheet of .060 styrene. The curbs are HO Scale 6"x6"strips rounded on the top edge with a file. Lines were taped off and painted using rattle cans. The patch work is various pieces of styrene glued to the surface.

The next example is a road on the opposite side of the same module which was done by Mark Gugliotta, another one of the prominent members of the Sipping & Switching Society. For this road surface Mark used Elmer's Wood Putty. Once the putty has dried, the road is shaped using a sanding block. Mark then painted the road using the same method as stated above.

Molds and Castings:

Grain Leg Head Assemblies

I

am making molds for my grain conveyor leg head assemblies. There are many

designs out there which are not commercially available. I will need a large

number of each and to make each one individually will be time consuming.

Instead, I am in the process of building masters for a number of different

grain elevator leg styles. I will then cast the conveyor heads out of

Alumilite.

The

grain leg for Morrice elevator is a Woodbury Elevator Equipment design which

was a local company that no longer exists.

More grain head assemblies have been completed. The top row is the Walthers Grain Conveyor head on the left and the RIX Conveyor head on the right. In the second row again is the gray Walthers Modern Conveyor head. To the left of it are smaller versions of the same style. Below, in the middle row, are assorted sizes of the GSI design. The next row down represents the Honeyville design. And the bottom row is the Woodbury design.

I finally got some time to build my mold boxes for the grain heads. I am also going to tinker with the Walthers Surge Bin top and bottom pieces when I begin working on Emmett and Lapeer. Both locations have multiple surge bins of varying sizes which I will have to scratch build.

The first step is to determine the area needed for the masters to fit with at least 1/4 inch of space on all sides. This will be the dimensions of the silicone mold.

The next step is to build a box to those dimensions using styrene.

After the box is complete, the components can then be glued in place. It is important that no open pockets are uncovered which would allow the silicone rubber to seep under. This will make it very difficult to remove from the master once the mold material has cured.

Next, all of the edges need to be sealed to ensure there are no leaks along the box edges. Superglue works well for this.

After the glued edges have dried, I then fill the box with water. This step will determine if there are leaks or not. Once I am satisfied that the box is watertight, I pour the water from the box into a clear sided plastic cup. I can then mark the outside of the cup and I know the volume of mold material I will need to mix to avoid waste.

I will be using Micro-Mark RTV Silicone Mold Rubber to make the molds for this project.

The RTV Silicone Rubber Molds are complete.

I don't normally weigh in on the conversations on social media sites in reference to scratch building, but this is a subject that I have often thought about in the past few years.

Being a Proto modeling person who enjoys scratch building, and the uniqueness that can be achieved using these skills, I find great satisfaction in reaching my goals of recreating an actual place in time. I also realize that not all modelers have, or develop the same skills as we strive toward our respective goals. One of the joys of this hobby that keeps me entertained is the fact that it is so diverse and multi-faceted that one always has something new that can be learned. We have to be a jack of all trades, and specialize in a select few.

Back to my point. With the introduction of new tools such as 3D printers, laser cutters, etc...we are seeing NEW TYPES of scratch building being accomplished. YES these are tools, and therefore only as good as the operator's skill in using them. And also, YES they do make some aspects more accomplish-able from the modeler who is under developed (or not) in traditional scratch building techniques. Certainly these tools will allow lesser developed modelers to overcome some deficiencies in skill, but they will also allow more skilled modelers to take the next leap into achieving highly detailed and accurate models perhaps more difficult or even impossible to achieve using traditional techniques.

Having broadened my skills now that I am dipping my feet in and testing the water in the CAD design world, I have a much better appreciation for the amount of skill and effort that goes into this approach.

I therefore suggest that maybe the real issue at hand when presenting scratch building projects that will help to clarify this is to categorize these skills into respective sub categories. They are all examples of scratch building, but I think most would agree that scratch building with traditional methods differs from scratch building with Laser, which in turn differs from scratch building with 3D printer, etc...Perhaps the solution is a clarification in the terminology used. For example: Scratch Built, Laser Scratch, 3D Scratch, etc...All require a degree of skill by the builder, and all produce outcomes reflective of the builder's skill level. Most importantly though is that all are representative of the diversity of skills associated with the hobby.

My two cents

Curves:

6ft Outside Radius Curves:

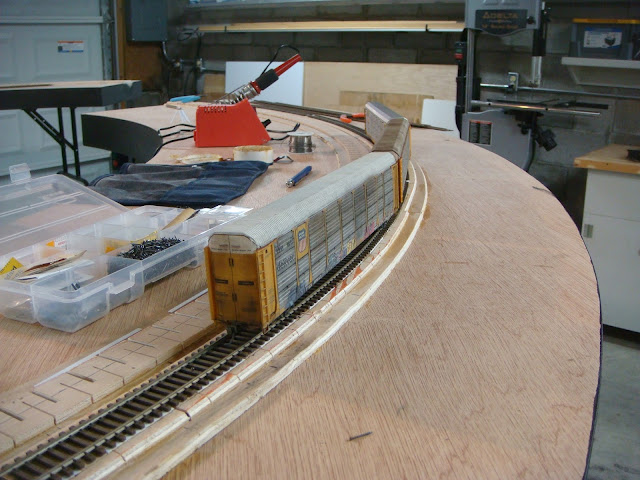

Now that I am finally back into the shop, module building has resumed. To start, I am getting track tacked down to my four corner modules in order to get trains running. These first four curves will get generic country scenery.

|

| 360 degrees of 6ft outside curves. |

| ||

| Cut with radius tool and notched on band saw. |

| |

| Inside track was notched straight cut roadbed. |

Here is the radius drawing too I made for these and future curves. With this tool I can draw track center lines, curves up to 8ft radius, and draw waffle bottom webbing.

Track work on the curves began with laying out vertical transitions for the super elevation. Below is an example. My vertical transitions are 20 inches long starting at level, and every 5 inches the outside rail is elevated in .010 increments up to the final height of .040.

|

| Super elevation strips |

The next few pictures show the process of positioning the alignment pins utilizing the template as a guide. The template is the key to insuring everything aligns correctly and is universally compatible with other modules in the layout or group.

In the first picture, the template is positioned and clamped in place so as to be square on the frontier face and even with the TOPS of the rail. This allows for any code of rail to be used. Using a 1" Forstner bit, lightly oiled to prevent damage to the template, the alignment pin holes are then started. These holes are drilled generally around 1/16" deep before stopping.

Next, the template is removed as shown below. From this point a drill guide can be attached if desired to ensure the holes are drilled perfectly straight the rest of the way through the end plate.

Next, the pins are installed. Pins are made from 1" tube stock epoxied in place. They are 1 1/2" in length to allow them to seat all the way through the 3/4" end plate and protrude 3/4" out.

After the epoxy has had time to set up (at least 24 hours) the pins can be notched for the bevel. I cut about 6 notches just under 1/2" deep into the 3/4" tube. This leaves around 1/4" of un-bevelled tube where the tables meet.

The weather was perfect today to get everything for the donut outside and tested. All electrical work is finished. The next step will be to get some trains running.

After getting all of the rail wiped clean, I was pleased to get a couple of trains running.

I began painting the track by spraying a base coat of Rustoleum Primer Gray. This was followed with a light coat of Krylon Satin Pebble that was applied at random around the loop. As stated elsewhere in my blog, this is an undercoat that will bleed through the final layers of wash. I am attempting to get more variation of cross tie color to the final outcome.

The next step is the wash of Burnt Umber Oil mixed with Mineral Spirits. This is applied in a heavy wash so that it pools on top of the ties for a period of time while drying. During this time, the Mineral Spirits are softening and blending the base color into the mix and allowing it to bleed through the wash.

After 24 hrs of drying time, the next wash is applied. This is Raw Umber Water Mixable Oil thinned with Ammonia and Distilled Water. The idea here is to apply a top coat wash that will not mix with the previous color blending. Once complete, I rolled everything outside in the sun to get a good look at the true color. After touching up a few areas, I let everything sit and dry.

Here is a closer look at the color blending.

After this wash, I always let everything sit for about 48 hours before painting the rail. While this was happening, the base cinder color for the roadbed was applied.

After allowing everything to dry for 48 to 72 hours, a spray of Dullcote was applied to lock everything in place. Next the rails were painted Rail Brown. For this, I used one of the paint markers rather than taping off and airbrushing as is my usual technique. Overall, I am fairly pleased with the results although I will have to do some touch ups in the areas that were difficult to reach with the marker. This is primarily along the bottom of the rail between the tie plates.

Here is a close up image showing contrast between the painted and unpainted rail.

The tree making effort is in full swing.

I will be experimenting with clippings from a Smoke Bush for tree and filler material. Below is a picture of the Smoke Bush material on the plant.

|

| SMOKE BUSH |

I spent the day battle testing my trackwork and stretching the legs on some of my power.

8ft Outside Radius Curves:

With the weather cooling down, module building has resumed. Here I am getting the reinforcement pads for the table legs glued in place on half of the 8ft donut. These are 24 inch deep modules. Currently, only 90 degrees are spoken for on the east end of East Durand. The remaining 270 degrees will be generic facilitators for the time being until a need for them arises.

Here is the complete 8ft donut. Since there is not an immediate need for them, I am opting to not put them up on legs at this time. This will make them much easier to transport in an anticipated move coming early next year.

28 April 2020:

Here is my new standard for Z-frame module construction that will save me a huge amount of time in finishing scenery as well as present a much cleaner look to the completed module face. The standard Z-frame module box is constructed in the same manner as was previously covered, but the width is the desired measurement MINUS two thicknesses of profile board. In my case, I will be using standard Luan for the profile board. These two boards can then be veneered directly to the sides of the Z-frame box to achieve the final width. In addition, a full height profile board is glued along the frontier. Once scenery is determined, a profile can then be cut to the appropriate height leaving a solid profile board with no seams that have to be covered and sanded. The process of construction takes almost no additional time vs. hours of headache using the traditional method. The module below also captured another idea that occurred to me as I looked at the pile of generic (no current theme) flat modules that I continue to construct using my scrap Luan. By having a number a 2ft transition modules to form bookends, I can put as many modules as needed in between these sets of bookends in order to represent raised fill. In the case of the module below, the frame drops 1.5 inches, but this can be any height desired.

3ft-11.5in Outside Radius Curves:

I built four 90 degree curve modules with an inside radius of 2' 6" and outside radius of 3' 11.5" These will nestle into the inside 4' radius of my 6ft curve modules with half an inch clearance. This will allow for maximum utilization of space The gap will be used for a backdrop to be placed on each module to visually separate sections of the layout. Initially these curves will be facilitators for a loop of track in my attic that I will use to test new modules as they come online. Eventually, all will be incorporated into the branchline portion of the layout between Durand and Owosso. My intent is to have this section of the layout isolated from the Mainline sections.

|

| This curve section will eventually become a portion of the passing siding in Corunna, MI |

Did you have any luck with Shapeways on your bridge railings? I'm modeling CSX/Conrail in Lansing an could use them on my Old US 27 bridge

ReplyDeleteNick, The short answer is no, I have not gotten any farther than the graphic design which I did on SketchUp during one of my business trips. I have this project and a couple others that I need to get off my butt and contact Shapeways about.

DeleteHow did you create the concrete bridge for the Joe Balint module? I love how the corners show effects of crumbling concrete.

ReplyDeleteThanks,

Gary

Gary, I apologize for it taking so long to get back to you. I scratch built abutments and the bridge itself out of styrene. The intermediate piers are Alumilite castings from a mold I created for the Fenton Rd (Grand Funk RR) bridge in Flint, MI. The spawling of the concrete is created with a Dremel tool.

Delete