ELEVATOR CONSTRUCTION:

After making a cardboard mock-up, I built the base shell out of .060 styrene. The window and door openings are roughed in at this point and will be refined as the project progresses.

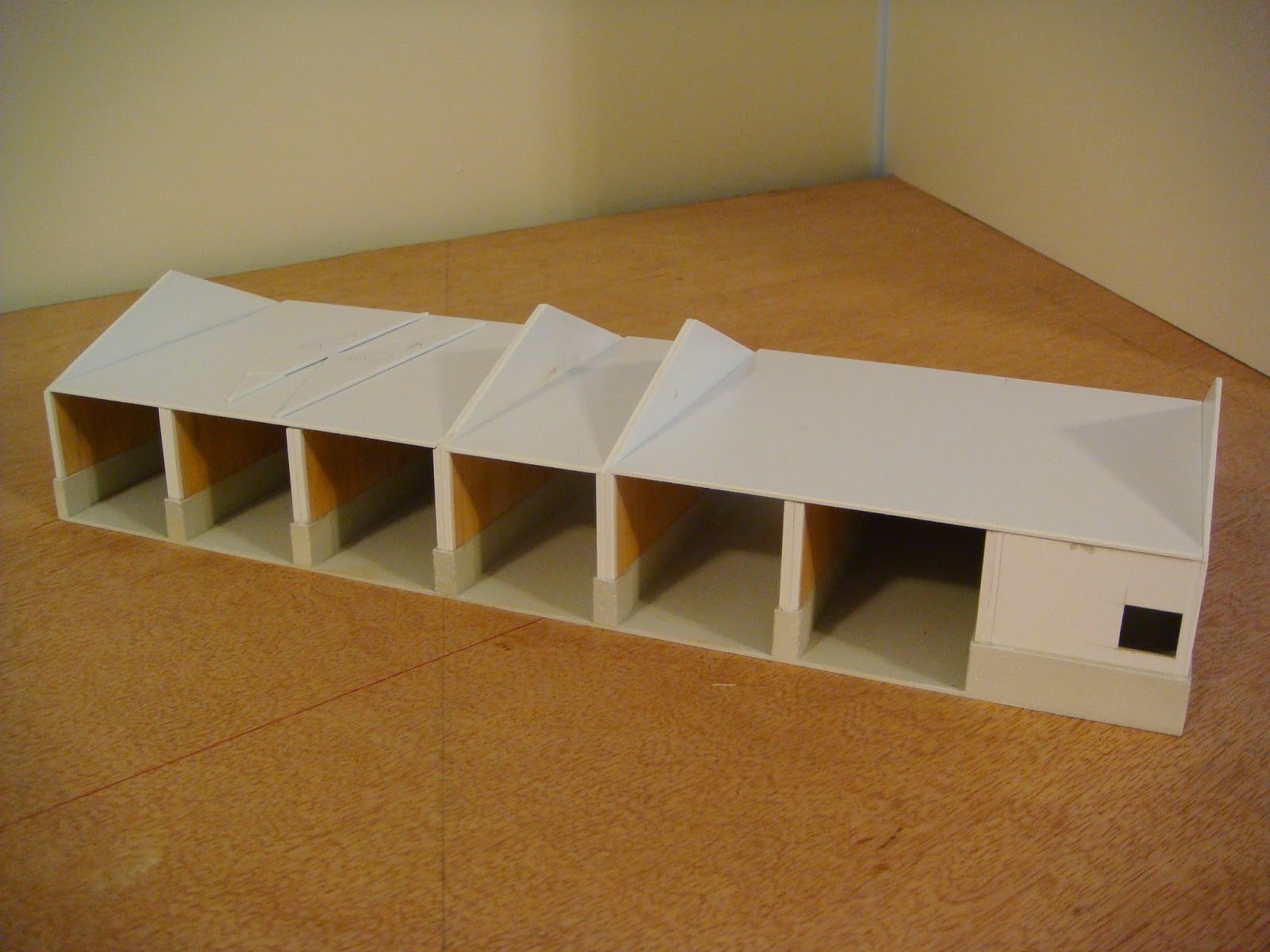

I have always liked the look of the Morrice elevator with the gambrel roof design which sets it apart from other elevators. The model is approximately 30 inches long.

Here is the completed shell minus the add on details.

Add on details and final foundation spalling.

VAN GILDER FARMS / VAN GILDER GRAIN:

I will be slightly compressing the warehouses in Morrice to allow the entire scene to fit into 18 linear feet. The scene will be divided across three 6ft modules. The first building will be the Van Gilder Grain storage facility. The actual building is around 120ft in length, however I will be compressing it down to 105ft. Again I am building the base shell out of .060 styrene. For the warehouses I am using textured styrene veneer as the outer facing.

I began by drawing the footprint of the building to scale to make sure that the dimensions of the selective compression were to my liking.

Next I cut out all of the components for the base shell.

Here the initial skeleton of the building is glued up.

All of the interior walls are glued into place and the building is ready for the initial concrete coloring.

For the base concrete color, I wanted to experiment a little. I started with my usual coat of Valspar Satin Hunter's White (unfortunately no longer in production). After this had dried, I misted Rust-oleum White Primer over it so that the original color was still slightly visible.

Here is the result. I am pleased with this as a base color.

Next I cut the wooden wall interiors out of 1/16" Balsa Wood, and colored them by rubbing AIM Dirty Yellow Weathering Powder. I then glued them in place with Amazing Goop.

Here the ceiling are cut and being test fitted. Unlike most of my other buildings, this one will not have a removable roof.

A few more details to complete and this structure will be ready for weathering. For the red, I purchased a can of gloss fire red spray paint from Walmart for $1.50. I think this is a good base color for farm equipment. I am not concerned with the gloss since there will be multiple layers of weathering sealed with dull cote between layers.

The next Van Gilder Grain building should be a very simple build in terms of the structure itself. At first I thought I may have been able to utilize a Pike Stuff warehouse, but the significant size will require scratchbuilding. I intend to build this structure completely out of styrene.

The shell is complete on the white building. The structure measures a scale 120' long and 50' wide.

The main bay doors have been installed and the base coat of paint is applied. Some of the detail on this structure will have to be put on hold until I can test fit it onto the module.

Most of the details have been applied. I ran out of siding material so the roof will have to wait for a couple weeks. For the louvered vents on both ends of the building I used clapboard siding cut to size and then framed with angle iron. I then glued an HO scale 1x2" down the middle. So far I am pleased with the results. I hope that once a wash is applied it will give them a little more depth.

BANCROFT TRUSS CO.

Bancroft Truss Co. was still open in the 1980's however it was no longer shipping or receiving loads by rail. I will have the spur track in place, so the option will be available to utilize modeler's license and add it back to the list of rail served industries on the layout.

MORRICE MODULE:

I have decided against the original module concept and replaced the three x 6ft sections that will make up the Morrice module. The new module consists of three x 8ft sections for Morrice proper along with additional sections that will complete the north and south sidings including the farmer's crossing west of town.

|

| Three 8ft sections with switch throw pockets. |

|

| Subroadbed and roadbed in place. |

|

| Track work complete for three main sections. |

|

| Final check of building locations as terrain is prepared. |

A 4ft section located on the east end of the module depicts the start of the north siding. Below you can see the track is painted with its base colors, and the terrain is being started with ground goop.

|

| Sanded grout, sifted dirt, and ballast layering. |

Track elevations can be seen more clearly in this low angle shot at the grade crossing at S. Morrice Rd.

Interesting modeling of a small town grain complex. I went to school with the Van Gilder family. The patriarch of the family, Fred Van Gilder passed away about a month ago. By his request, he was buried in a John Deere green casket. Have you explored their operation along the CSX tracks in Fowlerville. Very interesting buildings. The old Klein's Fertilizer operation next door is very model worthy also. Are you local to the area you are modeling?

ReplyDelete